China Sch 80 Seamless Pipe Factories - Cold extrusion technology of steel bar sleeve – Hengye

China Sch 80 Seamless Pipe Factories - Cold extrusion technology of steel bar sleeve – Hengye Detail:

Characteristics of cold extrusion technology of steel bar sleeve

(1) The construction technology of cold extrusion connection of steel bar sleeve is simple and easy to master.

(2) The steel bar sleeve cold extrusion connection technology can save a lot of time in construction compared with the traditional welding method.

(3) Compared with traditional steel bar welding connection construction, cold extrusion connection technology of steel bar sleeve can reduce the project cost.

(4) Cold extrusion connection technology of steel bar sleeve is suitable for radial extrusion connection of ribbed steel bar with diameter φ16-φ40 in reinforced concrete structure.

Technical requirements for cold extrusion of steel bar sleeve

Appropriate extrusion technology and reasonable acceptance standard must be adopted in the construction of ribbed steel bar extrusion connection to ensure that the construction quality fully meets the design requirements.

Materials and equipment for cold extrusion connection of steel bar sleeve

(1) Materials

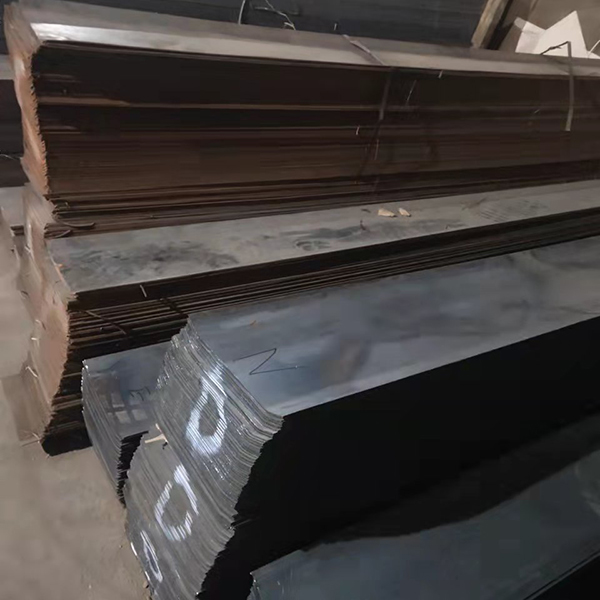

1, steel

The extruded steel bar must have a quality certificate, and its surface shape, size and mechanical properties should meet the requirements of national standards. Rebar must be inspected before use and samples taken for mechanical properties test. The chemical composition analysis should also be carried out when the brittle fracture and mechanical properties of reinforcement are obviously abnormal. When rebar is stored and transported, the surface mark shall not be damaged, and it shall be stacked neatly according to the batch to avoid corrosion and pollution.

2, the sleeve

The sleeve material is made of seamless steel tube suitable for calendering. The measured mechanical properties, sleeve size and deviation meet the requirements. The sleeves shall be protected against corrosion and pollution during storage and transportation, and shall be checked and accepted in batches during acceptance. The sleeves shall be piled up according to different specifications during storage, and the sleeves shall have factory certificate of quality.

(2) Equipment

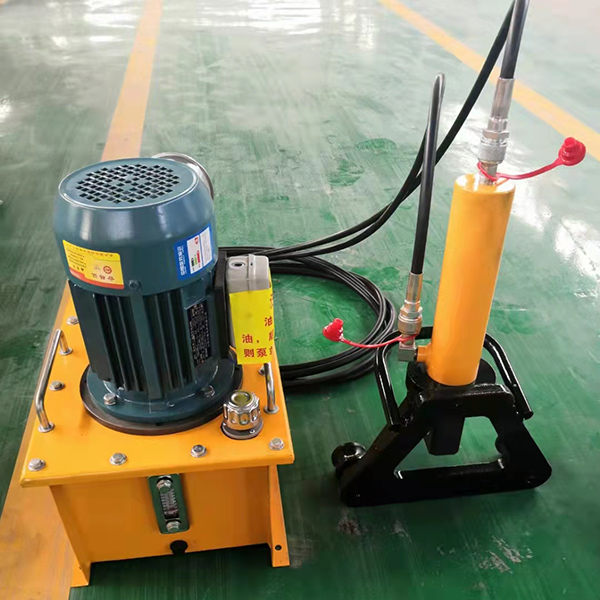

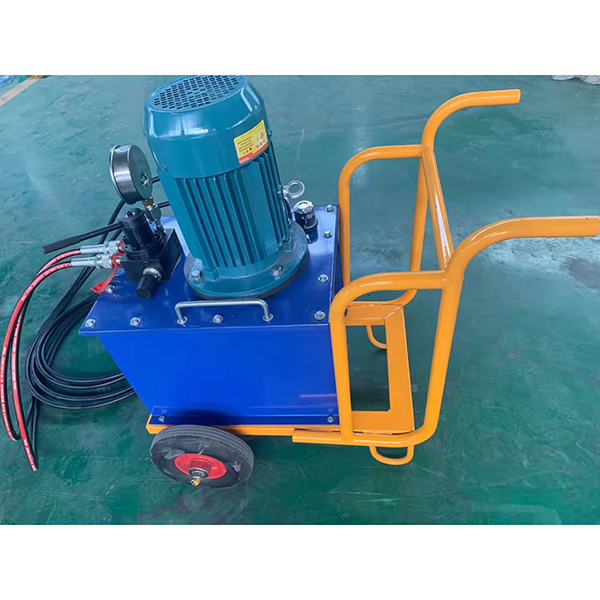

1, extrusion equipment

Extrusion connecting equipment is composed of crimper, ultra-high pressure oil pump and ultra-high pressure oil pipe. Ultra-high pressure oil pump is the power source of extrusion, rated working pressure is 80Mpa; Crimping device is the executive parts of steel extrusion, there are two models, the maximum working pressure of 100Mpa; Yjh-32 is suitable for crimping φ16-φ32 steel bars, yJH-40T is suitable for crimping φ32-φ40 steel bars. Press die, sleeve, steel bar should be used together, there are nine specifications of press die, the number marked on the die represents the diameter of the steel bar, should be checked when using.

The steel bar sleeve cold extrusion connecting equipment also includes extrusion auxiliary equipment and extrusion special equipment. Extrusion auxiliary equipment: spreader, angular grinder, etc.; Extrusion special equipment includes: mark card, size card board.

Three, the construction of cold extrusion connection of reinforced avenue tube

Cold extrusion connection construction operation procedure

1. Check whether the extrusion equipment is running normally before the cold extrusion connection operation of steel bar, and calibrate the extrusion pressure to meet the requirements before the operation.

2. Steel sleeve and mold are selected according to the specification of connecting steel bar. Mould models for connecting steel bars with the same diameter and mould models for connecting steel bars with reduced diameters should comply with relevant provisions in JGJ107 and JGJ108 respectively.

3. Remove rust, sand, oil and other sundries from the connected parts of steel bar.

4. Test the steel bar and steel sleeve. If the steel bar end has serious horseshoe, bent or oversized longitudinal rib size, it should be corrected in advance or polished with grinding wheel, but it is forbidden to polish the transverse rib of steel bar and cut the oversized part by electric welding.

5, with the depth ruler in the steel bar end paint positioning mark, positioning mark is inserted into the length of steel sleeve, check the mark distance from the positioning mark 15mm, to check whether the steel bar is inserted in place after crimping.

6. Insert the steel bar into the steel sleeve according to the positioning mark. The steel bar end should not be more than 5mm from the midpoint of the sleeve length.

7, according to the provisions of the pressing times and indentation of the pressing.

Product Display

Product detail pictures:

Related Product Guide:

With this motto in mind, we have become one of the most technologically innovative, cost-efficient, and price-competitive manufacturers for China Sch 80 Seamless Pipe Factories - Cold extrusion technology of steel bar sleeve – Hengye , The product will supply to all over the world, such as: Bogota, Burundi, Norwegian, Our company covers an area of 20, 000 square meters. We have more than 200 workers, professional technical team, 15 years' experience, exquisite workmanship, stable and reliable quality, competitive price and sufficient production capacity, this is how we make our customers stronger. If you have any inquiry, please do not hesitate to contact us.

It is a very good, very rare business partners, looking forward to the next more perfect cooperation!