China Seamless Pipe Per Kg Factories - Precision Seamless Steel Tubes – Hengye

China Seamless Pipe Per Kg Factories - Precision Seamless Steel Tubes – Hengye Detail:

Methods/steps

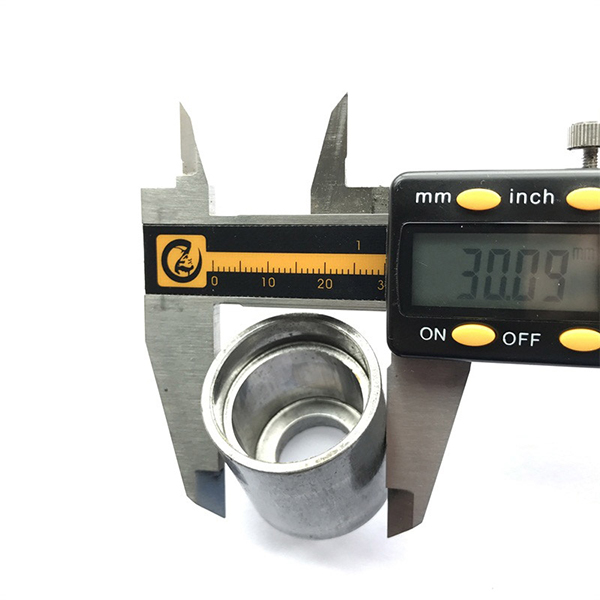

1. Seamless steel tubes are used for manufacturing various low and medium pressure boilers, superheated steam pipes, boiling water pipes, water-cooled wall pipes and superheated steam pipes, large smoke pipes, small smoke pipes and arch brick pipes for locomotive boilers. Use high quality carbon structural steel hot rolled or cold rolled (dial) seamless steel tubes. Mainly made of 10, 20 steel, in addition to ensure chemical composition and mechanical properties to do water pressure test, crimping, flaring, flattening and other tests. Hot rolling in hot rolling state delivery, cold rolling (dial) in heat treatment state delivery. The inner diameter of steel pipe is determined by the outer diameter length of drill bit of sizing machine.

2. Seamless steel tube after sizing, into the cooling tower, through water cooling, steel tube after cooling, will be straightened. After straightening, the steel tube is sent by conveyor belt to metal flaw detector (or water pressure test) for internal flaw detection. If there are cracks, bubbles and other problems inside the steel pipe, it will be detected. Shaanxi Huichuan sales of steel are from Laigang, Shougang, Baotou steel, Handan Steel, Metallurgical steel, Tang Steel, Jiusteel, Laigang, Angang, Longgang Ma Steel and other quality assurance steel mills, are in line with the national standard.

3. After quality inspection, paint on the pipe number, specification, production batch number and so on. And by the crane into the warehouse. Under the condition of the same cross section area, the steel pipe used for structure has stronger all-round bending resistance and better rigidity than square steel, flat steel and other types of steel, because the bending resistance of square steel, flat steel and various types of steel have strong directivity, but the bending resistance of steel pipe is not only no directivity, but also the strongest bending resistance per unit mass.

Product Display

Product detail pictures:

Related Product Guide:

We've got quite possibly the most state-of-the-art production gear, experienced and qualified engineers and workers, acknowledged top quality handle systems along with a friendly expert gross sales group pre/after-sales support for China Seamless Pipe Per Kg Factories - Precision Seamless Steel Tubes – Hengye , The product will supply to all over the world, such as: Milan, Qatar, Ethiopia, Insisting on the high quality generation line management and customers expert assistance, we now have designed our resolution to offer our buyers using the to start with amount getting and just after services practical experience. Maintaining the prevailing friendly relations with our buyers, we however innovate our solution lists all of the time to satisfy the brand new demands and adhere to the most up-to-date development of the market in Malta. We are ready to face the worries and make the improve to understand all the possibilities in international trade.

Timely delivery, strict implementation of the contract provisions of the goods, encountered special circumstances, but also actively cooperate, a trustworthy company!