Grouting sleeve is also called grouting sleeve joint or sleeve grouting joint.

The sleeve used for sleeve grouting joint is generally cast from nodular cast iron or high-quality carbon structural steel, and its shape is mostly cylindrical or spindle. Grouting material is a dry mixture composed of cement as the basic material, appropriate fine aggregate, a small amount of concrete admixture and other materials. After mixing with water, it has the properties of large fluidity, early strength, high strength and micro expansion. There are many kinds of sleeve grouting joints at home and abroad, and their forms are diverse, but according to the form of sleeve, it can be divided into two categories: full sleeve grouting joint and half sleeve grouting joint.

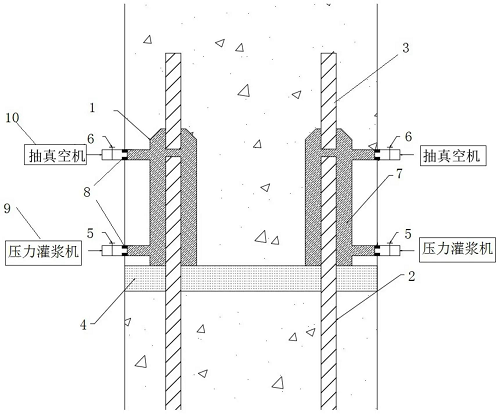

In practical engineering application, the sleeve is embedded into the connecting end of the component in advance when the prefabricated component is manufactured. During on-site construction, the exposed reinforcement of another connecting component is inserted into the sleeve. After the component is installed and positioned, the reinforcement is connected through grouting. Compared with welding and straight thread mechanical connection, sleeve grouting connection has the advantages of reducing the pre-processing workload of reinforcement, no secondary stress and deformation of reinforcement during on-site construction, and relatively large t-deviation can be accepted.

Post time: May-16-2022