Wholesale Din Seamless Pipe Factories - Cold heading sleeve Manufacturer – Hengye

Wholesale Din Seamless Pipe Factories - Cold heading sleeve Manufacturer – Hengye Detail:

The characteristics of cold heading forging process

1. Cold heading is done at room temperature. Cold heading can improve the mechanical properties of metal parts.

2. Cold heading forging process can increase material interest rate. It is a pressure machining method based on plastic deformation, which can realize less cutting or no cutting. General material utilization rate is in 85% above, highest can reach 99% above.

3. Can improve production efficiency. Metal product deformation time and process are relatively short, especially in the multi-station forming machine processing parts, can greatly improve productivity.

4. Cold forging technology can improve the surface roughness of products and ensure the accuracy of products.

Requirements of cold heading forging process on raw materials

1. The chemical composition and mechanical properties of raw materials should meet relevant standards.

2. Raw materials must be spheroidized annealing treatment, the metallographic structure of the material is spherical pearlite level 4-6.

3. The hardness of raw materials, in order to reduce the cracking tendency of materials as much as possible and improve the service life of the mold, cold-drawn materials are required to have as low hardness as possible to improve plasticity. The hardness of raw materials is generally required to be in HB110~170 (HRB62-88).

4. The precision of cold drawing material should be determined according to the specific requirements of the product and the process. Generally speaking, the accuracy of

5. The surface quality of cold drawing material requires that the lubricating film be dull dark, and the surface shall not have scratches, folds, cracks, hair, rust, oxide skin and pits pitting and other defects.

6. The total thickness of the decarburization layer in the direction of the cold drawing material radius should not exceed 1-1.5% of the diameter of the raw material (the specific situation depends on the requirements of each manufacturer).

7. In order to ensure the cutting quality of cold forming, cold drawing material is required to have a hard surface and soft core state. 8. Cold-top forging test should be carried out for cold-drawn materials, and the sensitivity of materials to cold-working hardening should be as low as possible, so as to reduce the increase of deformation resistance due to cold-working hardening during deformation.

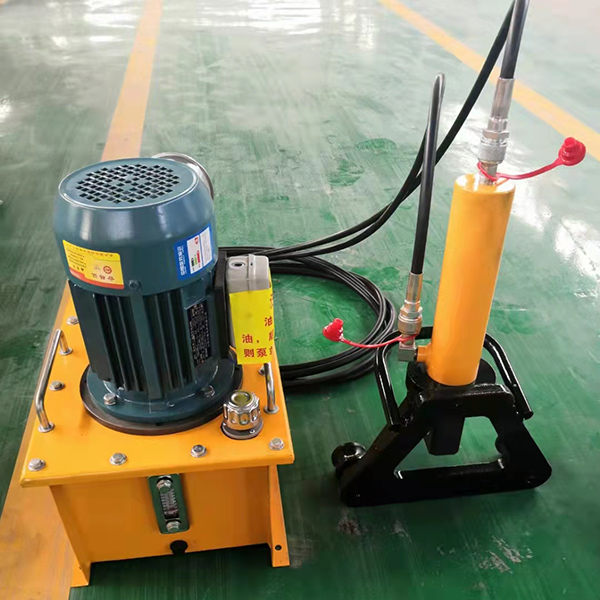

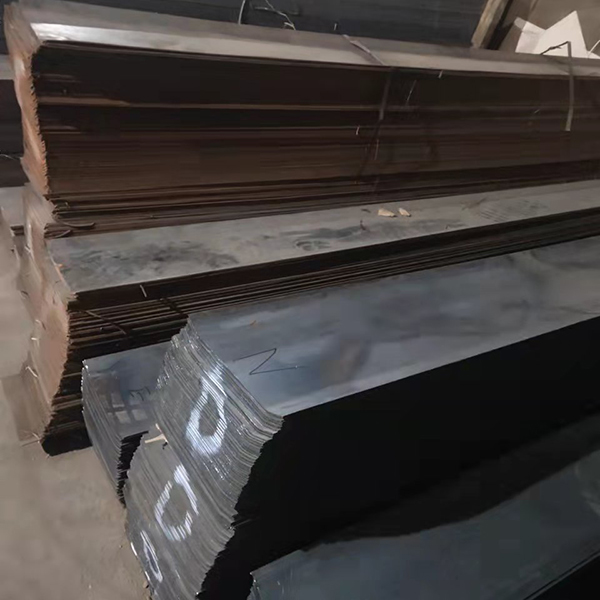

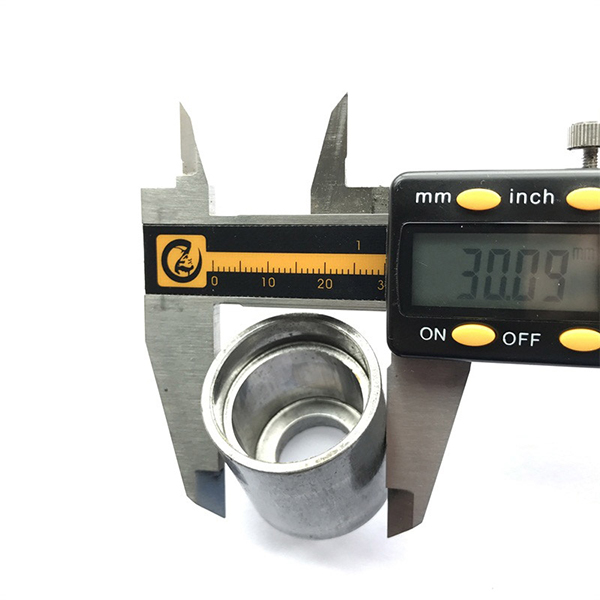

Product Display

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" is the persistent conception of our firm to the long-term to develop together with consumers for mutual reciprocity and mutual advantage for Wholesale Din Seamless Pipe Factories - Cold heading sleeve Manufacturer – Hengye , The product will supply to all over the world, such as: Croatia, Netherlands, Belgium, In the future, we promise to keep offer the high quality and more cost-effective products, the more efficient after sales service to our all customers all over the world for the common development and the higher benefit.

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.