Wholesale Seamless Steel Round Pipe Manufacturers - Stainless steel pipe Manufacturer – Hengye

Wholesale Seamless Steel Round Pipe Manufacturers - Stainless steel pipe Manufacturer – Hengye Detail:

According to the material, stainless steel pipe is divided into ordinary carbon steel pipe, high quality carbon structure steel pipe, alloy structure pipe, alloy steel pipe, bearing steel pipe, stainless steel pipe and bimetal composite pipe, coating and coating pipe to save precious metals and meet special requirements. There are many kinds of stainless steel tubes, different uses, different technical requirements, production methods are also different. The current production of steel pipe diameter range of 0.1-4500mm, wall thickness range of 0.01-250mm. In order to distinguish its characteristics, steel pipes are usually classified as follows.

Mode of Production

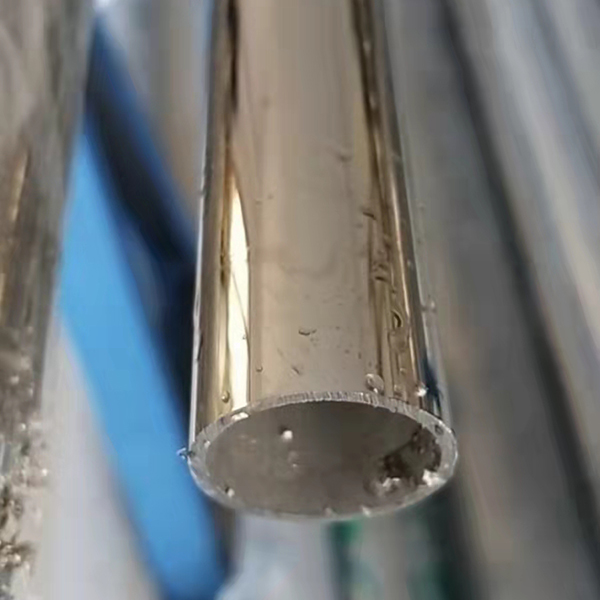

Stainless steel pipe according to the production method is divided into seamless pipe and welded pipe two categories, seamless steel pipe can be divided into hot rolled pipe, cold rolled pipe, cold drawing pipe and extrusion pipe, cold drawing, cold rolling is the secondary processing of steel pipe; Welded pipe is divided into straight seam welded pipe and spiral welded pipe.

The Section Shape

Stainless steel pipe can be divided into round pipe and special-shaped pipe according to the cross-section shape. Special-shaped tube has rectangular tube, lozenge tube, elliptic tube, hexagonal tube, eight direction tube and all sorts of section asymmetry tube to wait. Special-shaped tubes are widely used in various structural parts, tools and machinery parts. Compared with the round tube, the special-shaped tube generally has a larger moment of inertia and section modulus, has a larger bending, torsion resistance, can greatly reduce the weight of the structure, save steel.

Stainless steel pipe can be divided into equal section pipe and variable section pipe according to the longitudinal section shape. Variable section pipe has conical pipe, ladder pipe and periodic section pipe, etc.

Tube Shape

Stainless steel pipe can be divided into light pipe and wire pipe according to the state of the pipe end (with threaded steel pipe). Turning wire pipe can be divided into ordinary turning wire pipe (water, gas and other low-pressure pipe, using ordinary cylindrical or conical pipe thread connection) and special thread pipe (oil, geological drilling pipe, for important turning wire pipe, using special thread connection), for some special pipe, in order to make up for the influence of thread on the pipe end strength, The pipe end is usually thickened (inside, outside or inside) before the wire is spun.

Use Classification

It can be divided into oil well pipe (casing, tubing and drill pipe), pipeline pipe, boiler pipe, mechanical structure pipe, hydraulic prop pipe, gas cylinder pipe, geological pipe, chemical pipe (high-pressure fertilizer pipe, petroleum cracking pipe) and ship pipe.

Stainless Steel Welded Pipe Production Process

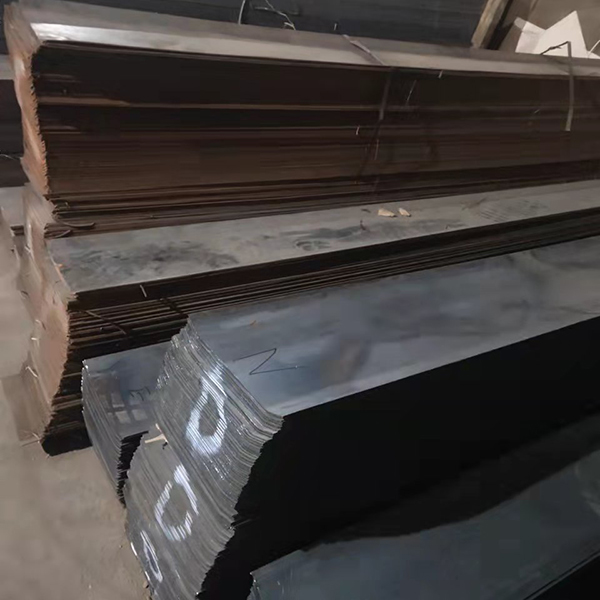

Raw material – swatch – welding pipe – end – polishing – inspection (printing) – packaging – shipment (warehousing) (decoration welded pipe).

Raw material – article points – welding pipe, heat treatment, correct, straightening, fix the end, pickling, water pressure test, inspection (spurts India) – packaging – shipment (transport) (tube) for piping weld pipe industry.

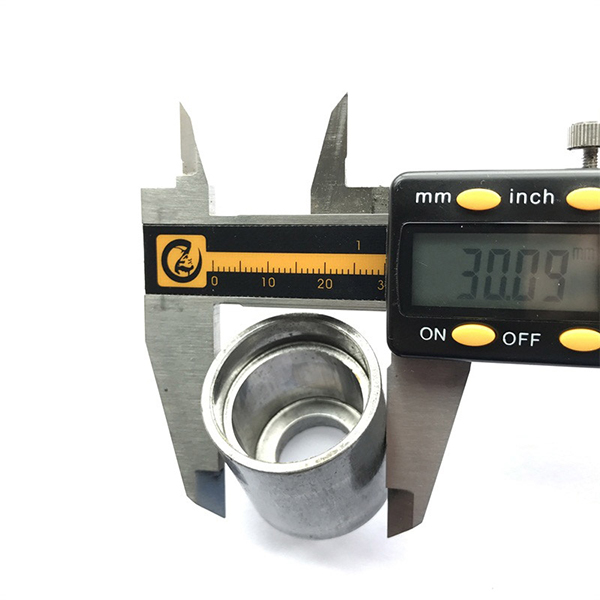

Product Display

Product detail pictures:

Related Product Guide:

We generally believe that one's character decides products' top quality, the details decides products' high-quality ,along with the REALISTIC,EFFICIENT AND INNOVATIVE team spirit for Wholesale Seamless Steel Round Pipe Manufacturers - Stainless steel pipe Manufacturer – Hengye , The product will supply to all over the world, such as: Victoria, Albania, Singapore, We have constructed strong and long co-operation relationship with an enormous quantity of companies within this business overseas. Immediate and specialist after-sale service supplied by our consultant group has happy our buyers. Detailed Info and parameters from the merchandise will probably be sent to you for any thorough acknowledge. Free samples may be delivered and company check out to our corporation. n Portugal for negotiation is constantly welcome. Hope to get inquiries type you and construct a long-term co-operation partnership.

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.